A year of monumental undertakings

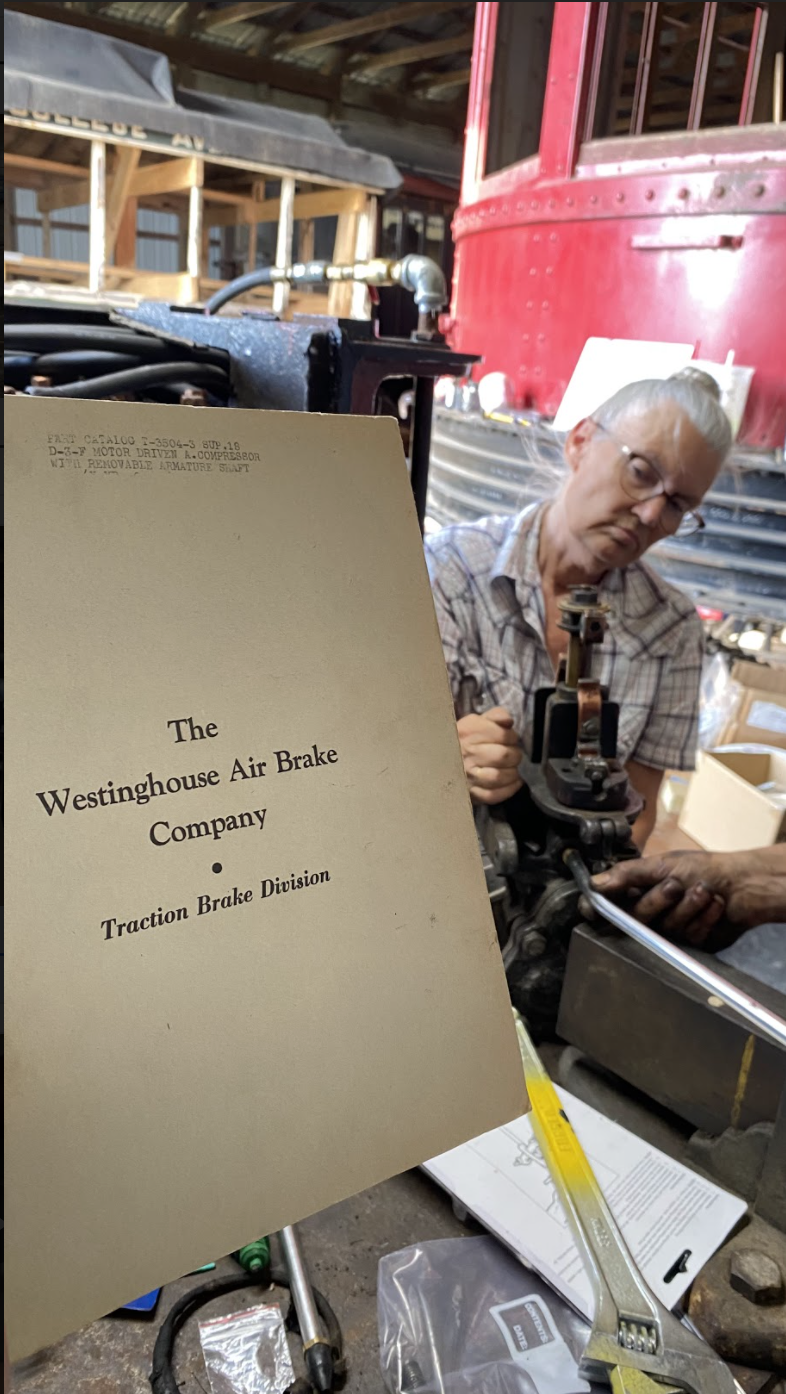

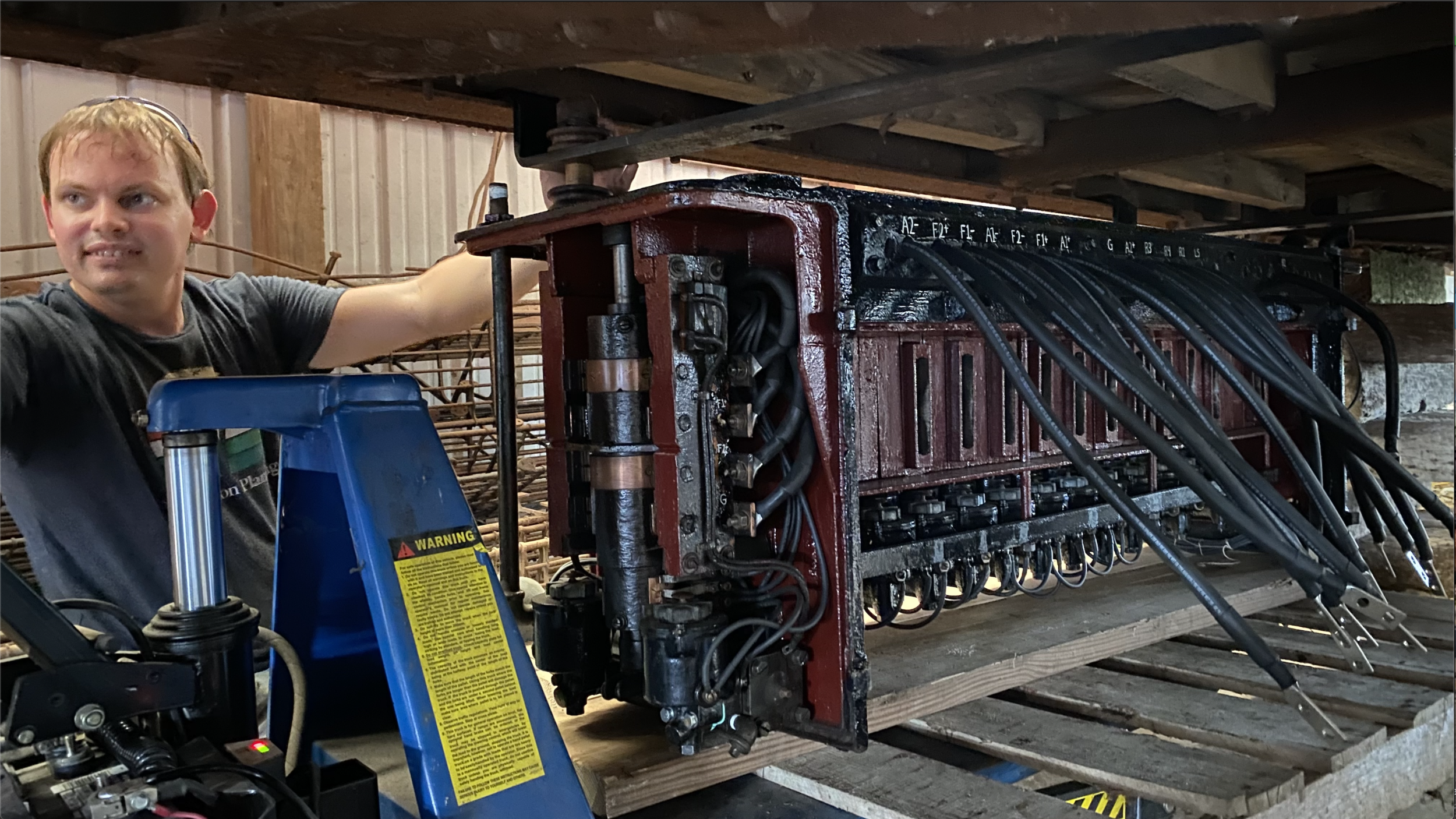

Volunteers work on the group switch in-front of interurban no. 429 - a component vital to the acceleration, deceleration and direction of travel of the interurban car.

2021 was another year of growth and progress for the nonprofit Hoosier Heartland Trolley Company, as the organization not only moved Union Traction Co. interurban no. 429 closer to revival, but also expanded capacity and resources. The organization took steps to once again engage the community in its historic preservation efforts face-to-face, as the pandemic has made such meaningful connections difficult for the better part of two years.

As we share this exciting update of tangible progress to bring one of Indiana’s last interurbans back to life, the board of directors is actively working with funders, community stakeholders and local leaders to identify a permanent site for the state’s only electric heritage railroad. We hope you find our progress inspiring and consider a tax-deductible donation or membership to support this project, which will facilitate educational, community placemaking and economic development opportunities for Hoosiers.

Historic preservation takes a full community of support. Host your own Giving Tuesday Facebook fundraiser for HHTC on Tuesday, November 30, 2021.

Phase II - mechanical progress

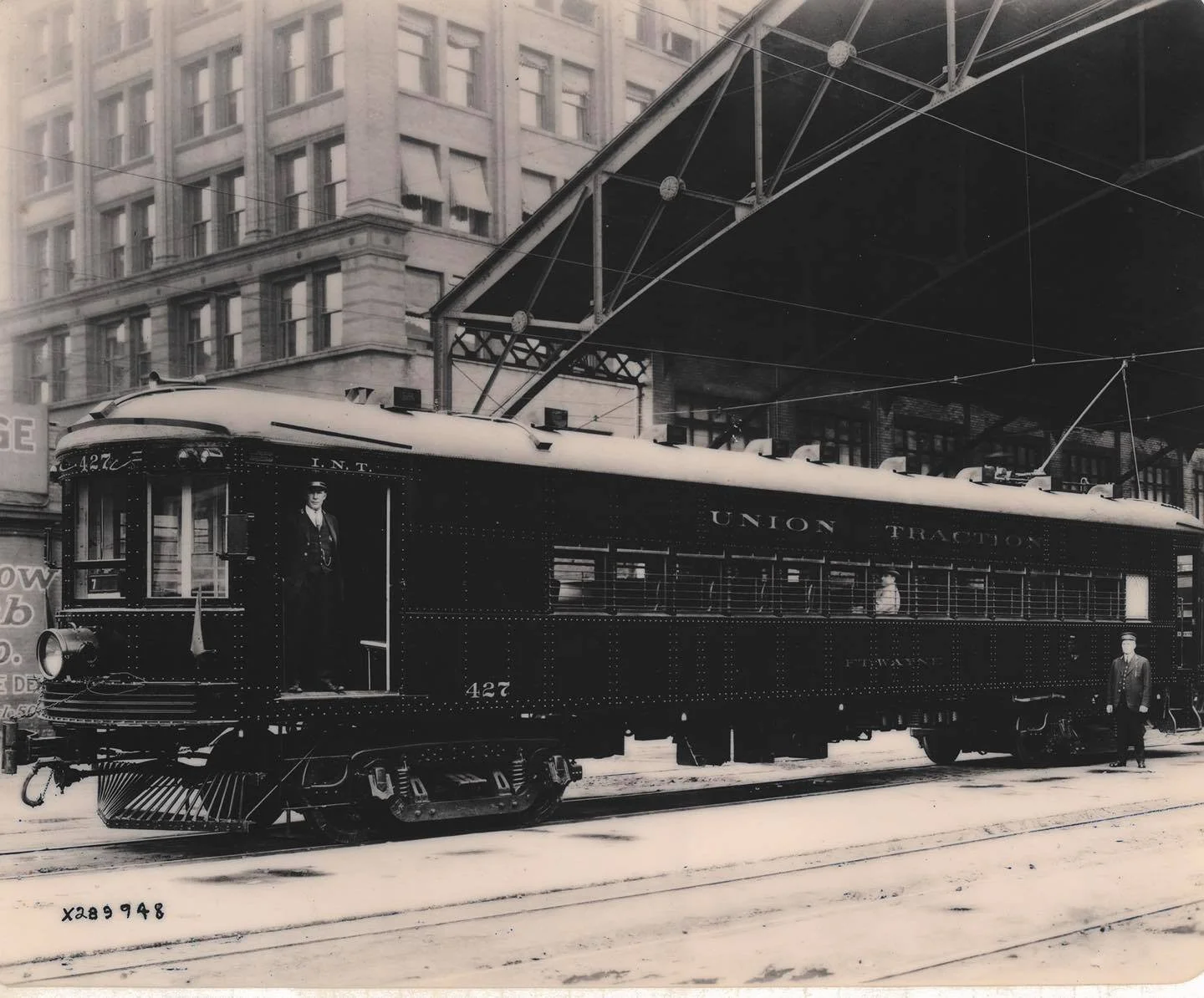

Union Traction interurban no. 427, sister to no. 429, rests in the Indianapolis Traction Terminal in the late 1920s. Krambles-Peterson Archive.

Thanks to a Heritage Support Grant provided by the Indiana Historical Society and made possible by Lilly Endowment, Inc., four vital components, which regulate the car’s propulsion and braking systems, were completely rebuilt and re-wired.

Interurban no. 429 was converted into a gravel pit office in Indianapolis after it was taken out of service in 1940, and as such, was completely stripped of all components necessary for its functionality. The car was reduced to a steel body on blocks, and has remained in a similar state for the past 80 years.

The prospect of returning interurban no. 429 to operational condition, along with the other cars in the HTHC collection, required sourcing adequate substitute components. Luckily, parts were obtained from 1920s-era Chicago L commuter cars, which used components from the same period and were in common use through the 1970s. Components acquired from the Chicago L cars were originally wired for rapid-start-and-stop commuter service, and thus required engineering work to mirror interurban components used for high-speed intercity travel. HHTC is lucky to have more than 100 combined years of restoration and railroad preservation experience in-house to perform this work. As part of the grant, an antique electric machinery consultant from Ohio was engaged.

The line switch

In some ways similar to a surge protector, the line switch protects the rest of the car in that it is the first component that receives electricity from the pole and overhead trolley wire. This component also engages when the car is put into motion, and helps to protect the car from power fluctuations.

The line switch also protects the car from overloading power to the motors and contains a voltage converter for items such as lights. The line switch was completely re-conditioned and re-wired to meet interurban no. 429’s needs. This subproject required the rebuilding of air pistons, electrical contactors and several other small components. The line switch is now operational and hangs underneath interurban no. 429 next to the group switch in its original location.

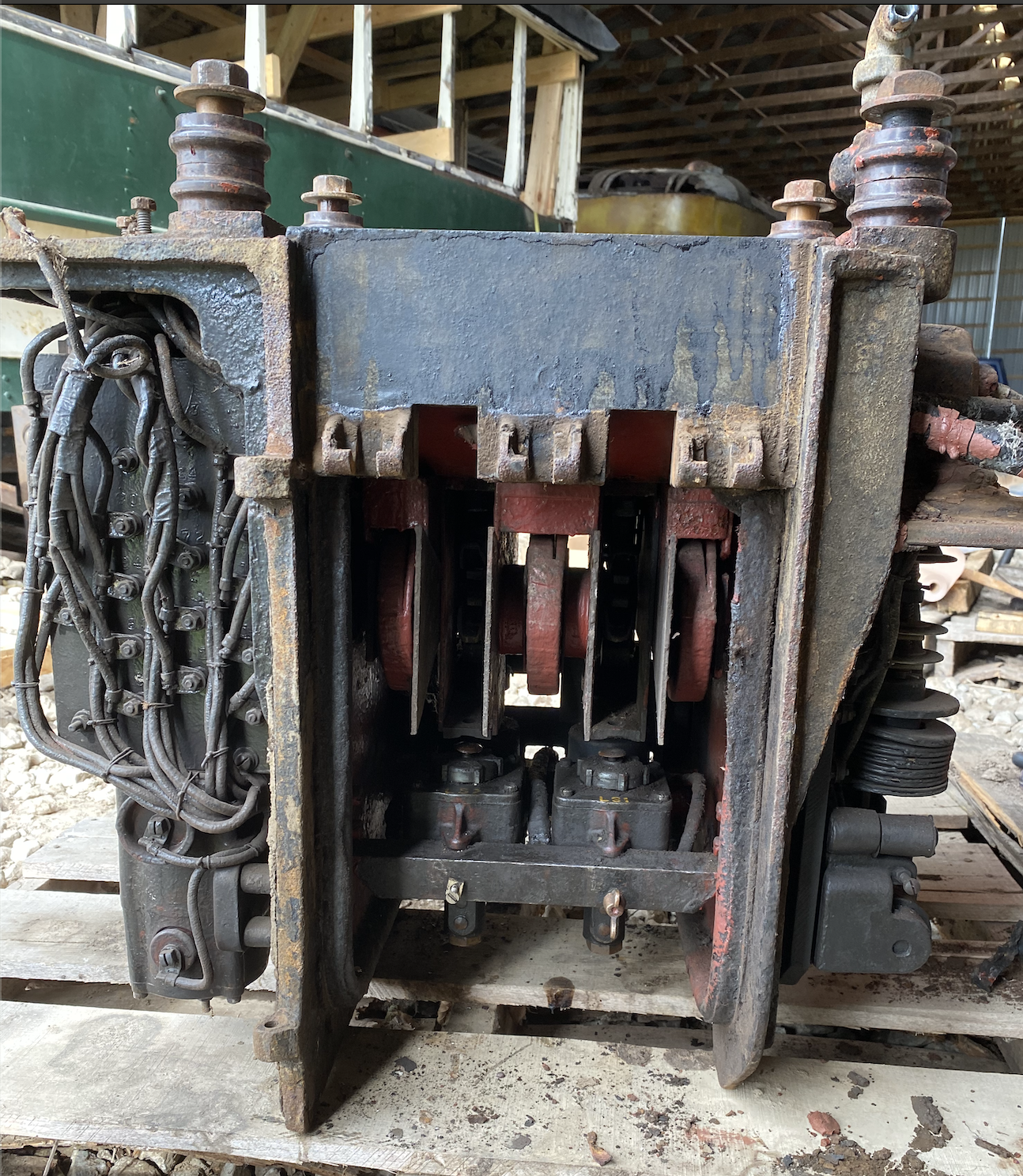

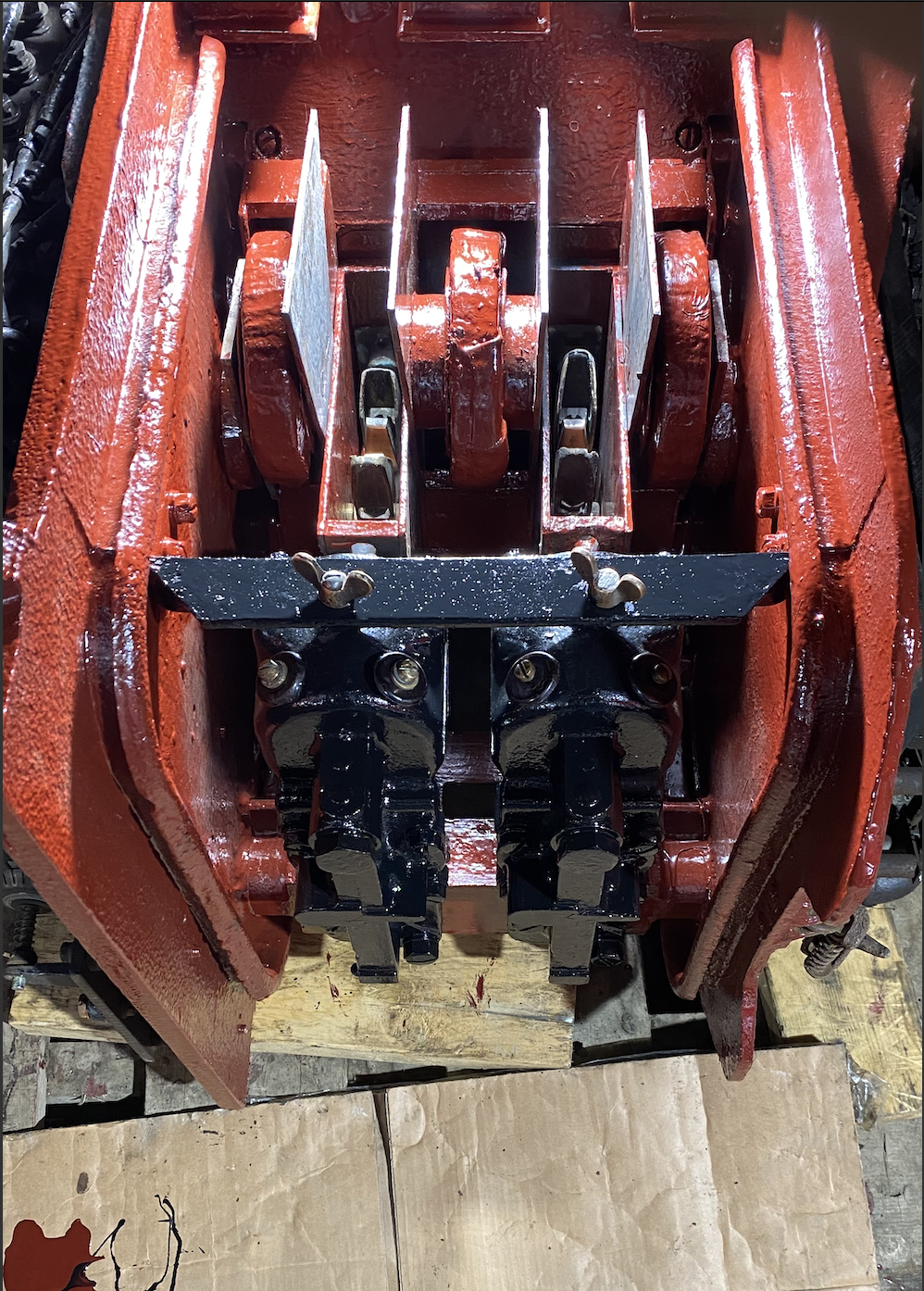

The group switch

This odd, one-ton rectangular component is much like the transmission on a vehicle in that it can change the direction of the interurban as well as the rate of acceleration and deceleration. Volunteers disassembled, cleaned, insulated and re-wired the group switch to mirror the original switch that hung under the car nearly 80 years ago. This component is now operational and installed underneath the car.

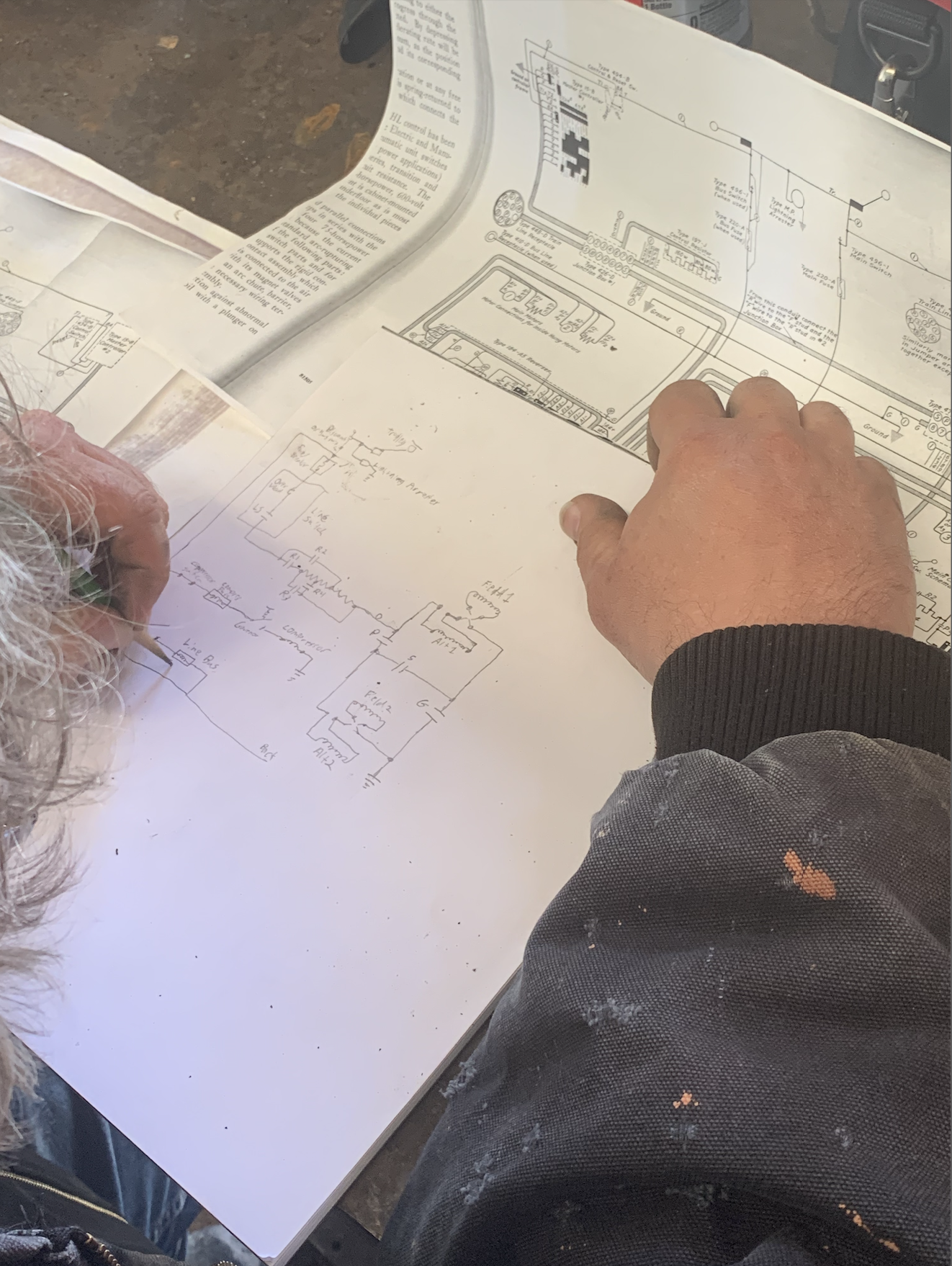

This several-month subproject required hundreds of feet of new wiring, rebuilt air pistons, a gallon of the insulation coating (Glyptal) and the reconditioning of nearly one hundred other small components. Engineering work to reconfigure the group switch for an interurban required the consultation of century-old diagrams.

the air compressor

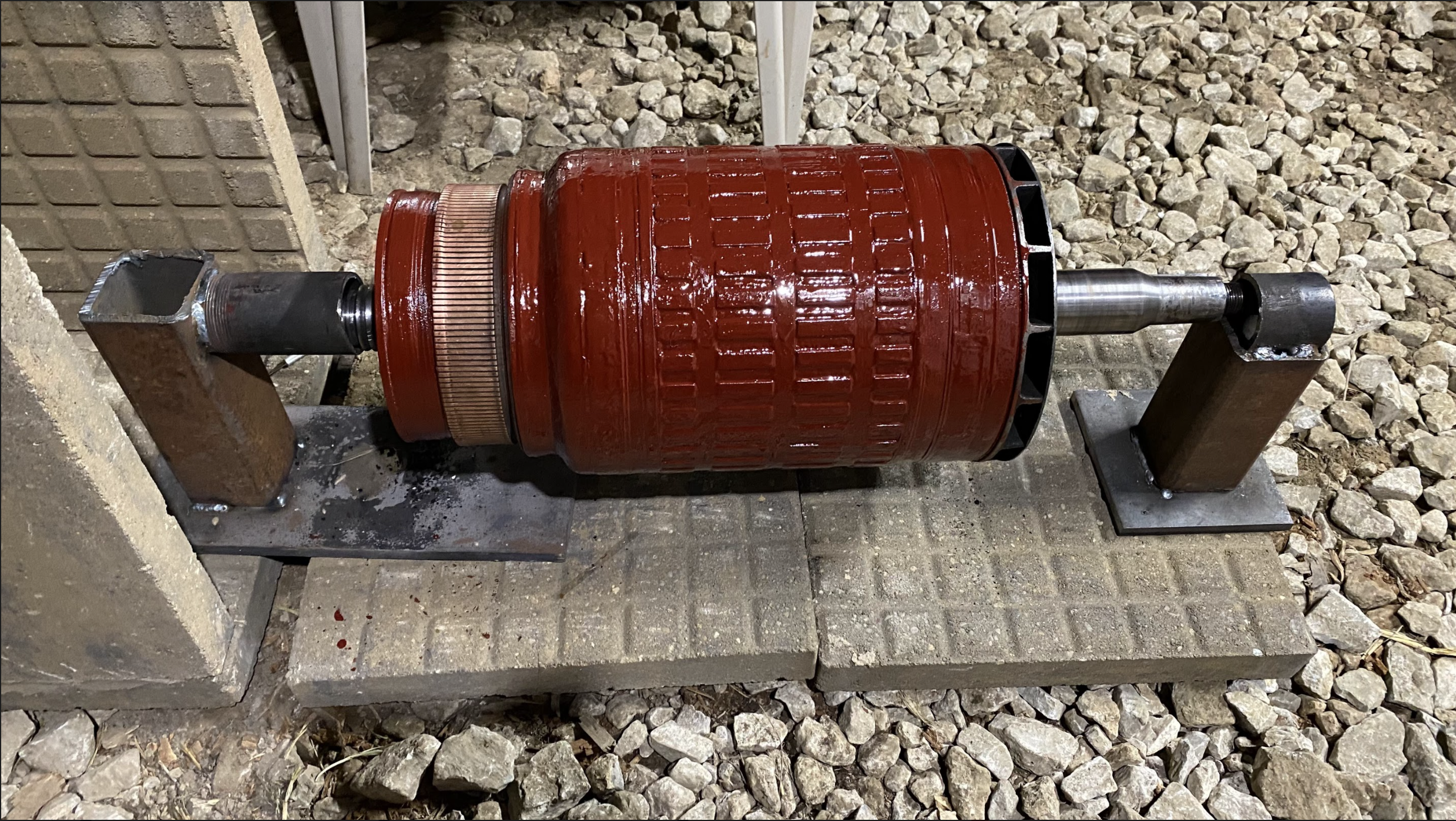

The air compressor is important to the interurban’s functionality and safety. Not only does this motor-driven air compressor pump air for the car’s brakes, it also provides air for the aforementioned group and line switches to function. This component was completely stripped down, cleaned and received new gears as well as motor work. The 150-pound motor was removed, baked in a custom-built oven to drive out moisture, insulated and then re-installed.

A cradle originally hung underneath no. 429 to hold the compressor; long gone, a new cradle was fabricated from scratch using prints obtained from overseas. This component is now operational and was hung underneath the interurban in its original location. The governor, which is a device that turns the compressor on and off to pump more air when needed, was also rebuilt.

The air compressor was successfully tested underneath interurban no. 429 - marking the first time one has operated on the car in nearly 80 years. Additional stabilization and bracing work will be completed as part of the custom-fabricated cradle shown on the car.

The controller

While the pandemic continued to complicate volunteer participation, our consultant was able to rebuild interurban no. 429’s controller remotely in Ohio. This component, made up of two handles - one to change direction and one to control the car’s acceleration, is the main control used by the motorman when operating the interurban - along with the brake handle. When the controller is activated, a drum spins inside touching various metal contacts and fingers, which send electrical signals down to the aforementioned group and line switches underneath the car.

Interior work - Smoking Section

The fall of 2021 was spent re-conditioning overhead lights for interurban no. 429’s interior, which are original to the car. Original brass windows and window tracks, also known as sash, were cleaned, refurbished, and for some windows, re-installed.

Looking Ahead to 2022

Next year’s focus will pertain to the completion of truck rebuilds (steel housings which hold the motors, wheels and suspension), wheel work, air brake system piping and additional electrical work underneath interurban no. 429. This work will progress the car’s restoration evermore near to operational status - marking the first time an Indiana interurban has operated in the Hoosier state in more than 80 years.